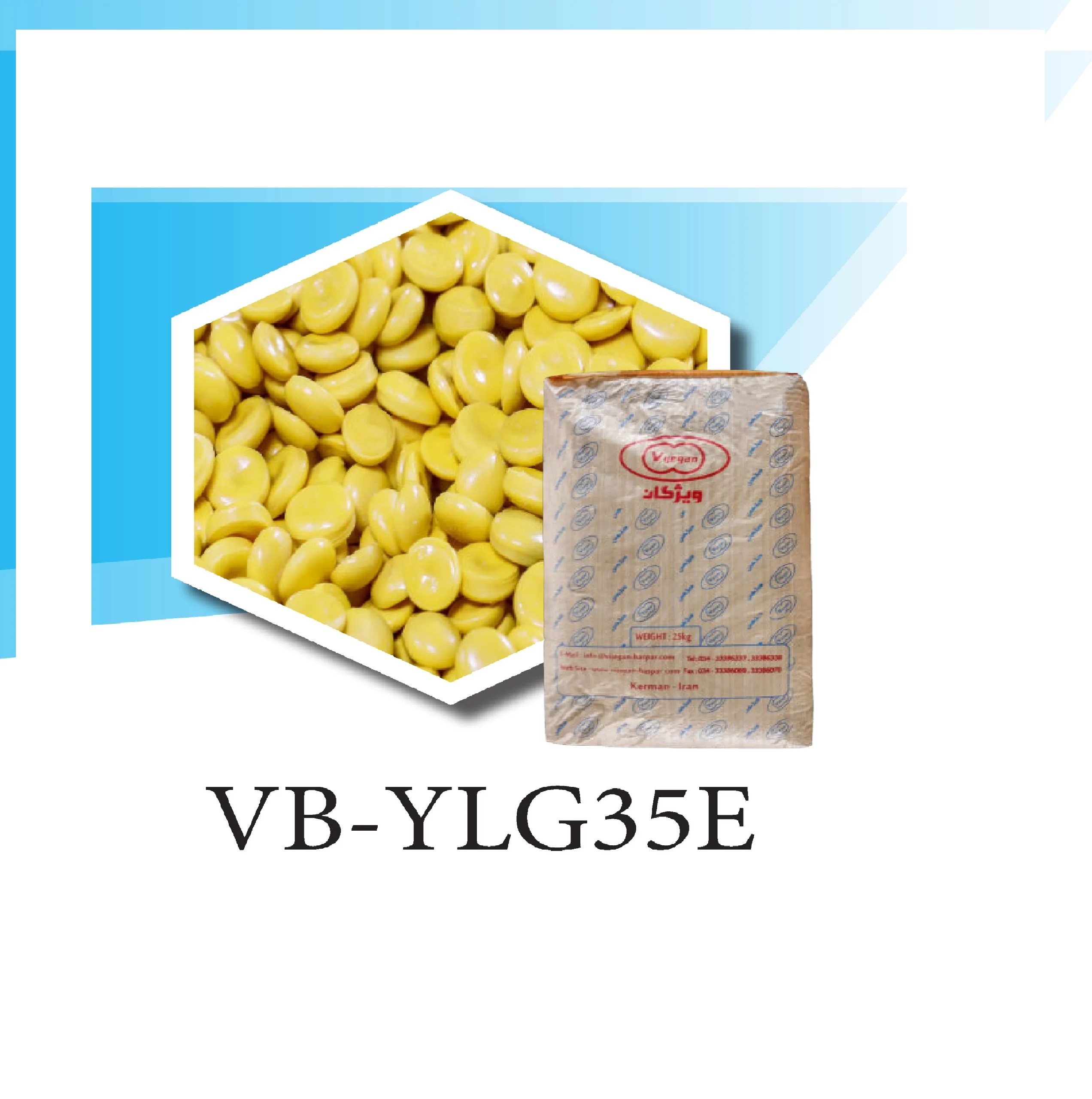

Yellow high density PE100 grade is designed especially for yellow gas strips of the gas pipes.

The use of appropriate antioxidants and stabilizers leads to the excellent resistance of this product against the UV rays of the sun and color stability, which ensures good quality and color on the pipe for a long time.

The high tensile strength of this product also causes a long life and proper performance in the pipe produced with this product.

| COMMERCIAL NAME :VB-YLG35E |

| Technical Name : Yellow HDPE for Gas Pipe Stripes |

| Description: VB-YLG35E is yellow high density polyethylene compound classified as PE100. It is includes a combination of antioxidant and stabilizer to ensure excellent lond-term UV resistance. It also gives good properties. |

| Color : yellow |

| Packaging : 25 Kg bag |

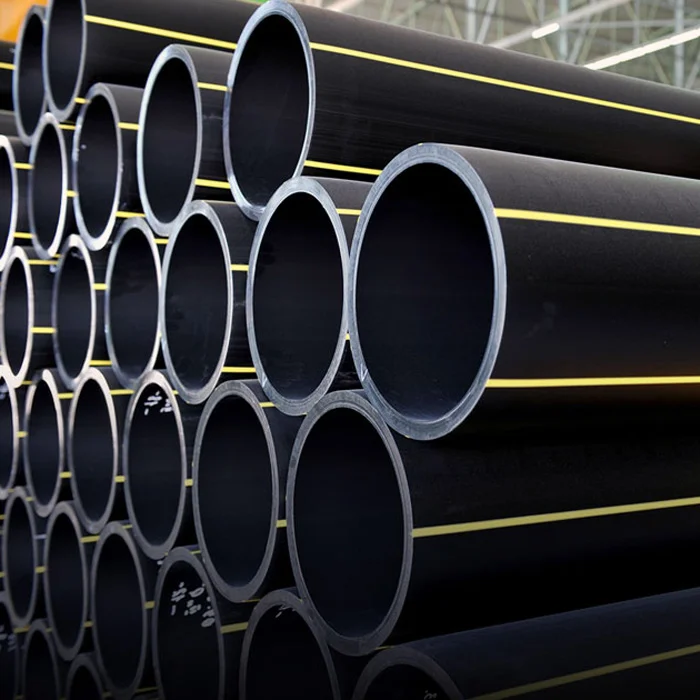

| Application :VB-YLG35E is especially designed for polyethylene gas pipe stripes |

| TECHNICAL DATA SHEET | |||

| Value | Unit | Test method | Property |

| 0.25± 0.05 | g/10 min | ISO 1133-1 | MFI (5kg , 190 °C) |

| 0.945 < | g/cm3 | ISO 1183-1 | Density |

| 21≤ | M pa | ISO 6259-1,3 | Tensile strength at yield |

| ≥ 400 | % | ISO 6259-1,3 | Elongation at break |

| 134±1 | °C | ISO 306 | Vicat softening point (1kg) |

| 85±1 | °C | ISO 306 | Vicat softening point (5kg) |

| 133 | °C | ISO 11357-1 | Melting point (DSC Method) |

| 350≥ | ppm | EN 12099 | Volatile content |

| > 100 > 165 > 1000 | hours | ISO 1167 | Internal pressure resistance At 20°C 12 Mpa– At 80°C 5.4 Mpa– At 80°C 5 Mpa– |

| > 25 > 50 | min | ISO 11357-6 | OIT At 210 °C – At 200 °C – |

| 55±1 43±1 | °C | ISO 75-1 | Heat Deflection Temp (HDT) At 1.8 Mpa (Method A)– At 8 Mpa (Method C)– |