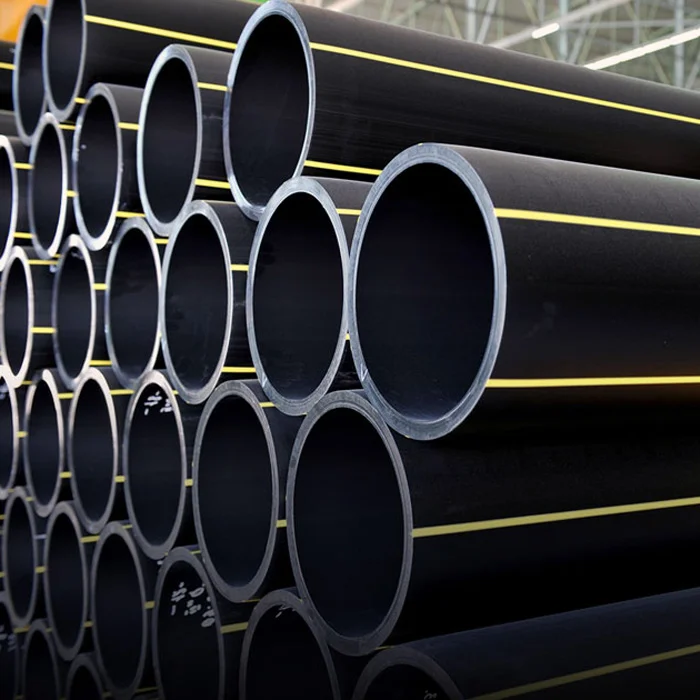

Black High density PE100 grade is specially designed for the production of polyethylene pipes with HDPE baseespecially gas pipes and fittings. The use of carbon black with high quality and small particle size and advanced production technology has led to proper and suitable distribution of carbon black in the product, which provides good resistance against ultraviolet rays.

The pipe produced with this product has high durability and strength, good resistance to internal pressure, impact resistance, resistance against slow crack growth and resistance to fast crack growth. So that it has high durability and longevity in practical operation. .

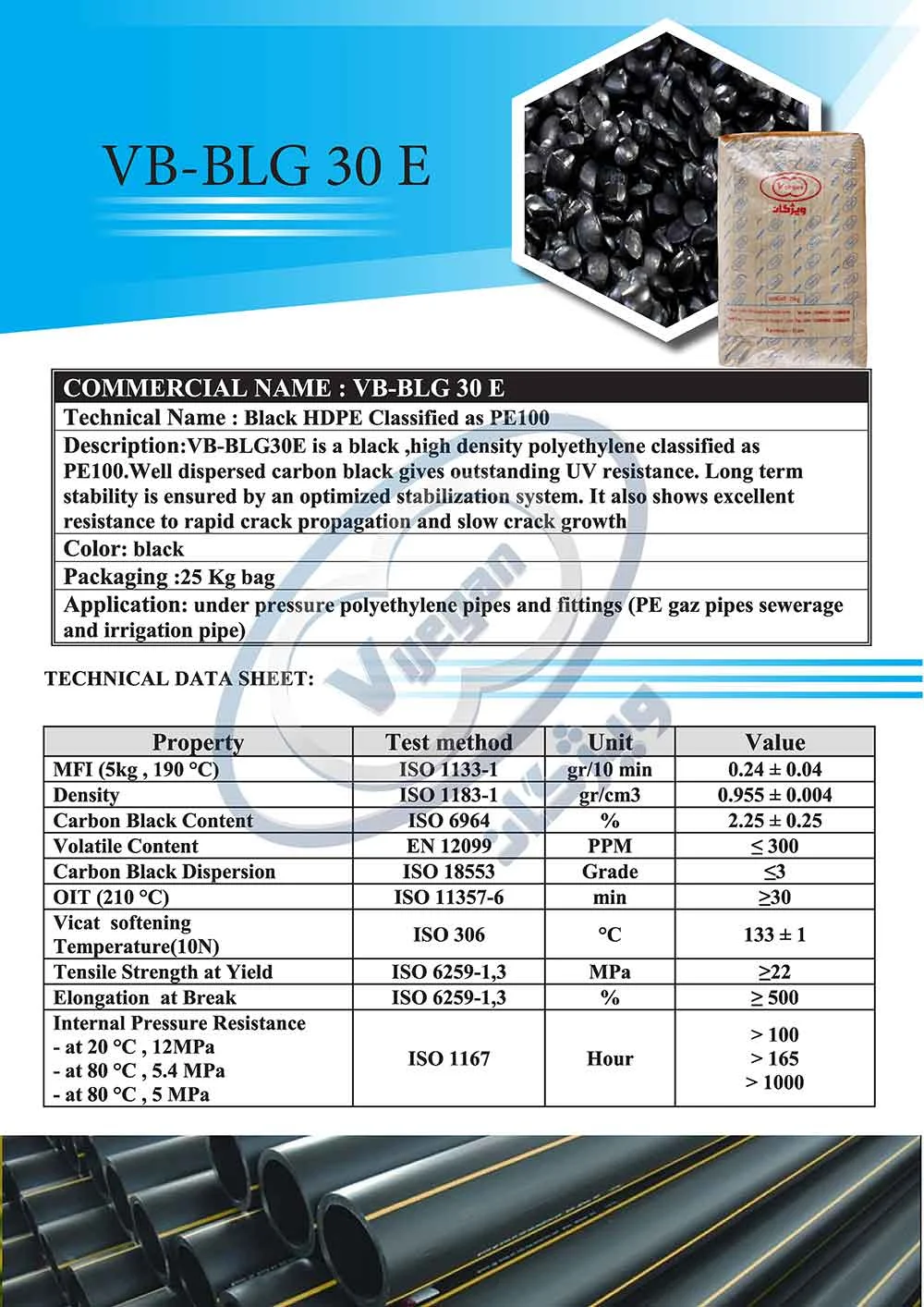

| COMMERCIAL NAME : VB-BLG 30 E |

| Technical Name : Black HDPE Classified as PE100 |

| Description:VB-BLG30E is a black ,high density polyethylene classified as PE100.Well dispersed carbon black gives outstanding UV resistance. Long term stability is ensured by an optimized stabilization system. It also shows excellent resistance to rapid crack propagation and slow crack growth |

| Color: black |

| Packaging :25 Kg bag |

| Application: under pressure polyethylene pipes and fittings (PE gas pipes sewerage and irrigation pipe) |

| TECHNICAL DATA SHEET | |||

| Value | Unit | Test method | Property |

| 0.24 ± 0.04 | g/10 min | ISO 1133-1 | MFI (5kg , 190 °C) |

| 0.955 ± 0.004 | g/cm3 | ISO 1183-1 | Density |

| 2.25 ± 0.25 | % | ISO 6964 | Carbon Black Content |

| ≥ 300 | PPM | EN 12099 | Volatile Content |

| ≥3 | Grade | ISO 18553 | Carbon Black Dispersion |

| ≤30 | min | ISO 11357-6 | OIT (210 °C) |

| 133 ± 1 | °C | ISO 306 | Vicat softening Temperature(10N) |

| ≥22 | Mpa | ISO 6259-1,3 | Tensile Strength at Yield |

| ≥ 500 | % | ISO 6259-1,3 | Elongation at Break |

| > 100 > 165 > 1000 | Hours | ISO 1167 | Internal Pressure Resistance – at 20 °C , 12Mpa – at 80 °C , 5.4 Mpa – at 80 °C , 5 Mpa |