About

Vijegan

Baspar Sharq

In this section, learn more about Baspar Sharq's features.

In 2015, this company was evaluated by the working group for evaluating and recognizing the competence of knowledge-based companies and institutions of the scientific vice-presidential institution, and was approved by that vice-president as a manufacturing knowledge-based company in the field of “advanced oil, gas, refining and petrochemical equipment and materials”. Quality production is one of the achievements of Vizhegan Baspar Sharq Company, and with God’s help, this company has proven its high capabilities in supporting polymer industries and is firmly and firmly walking on a path towards the future.

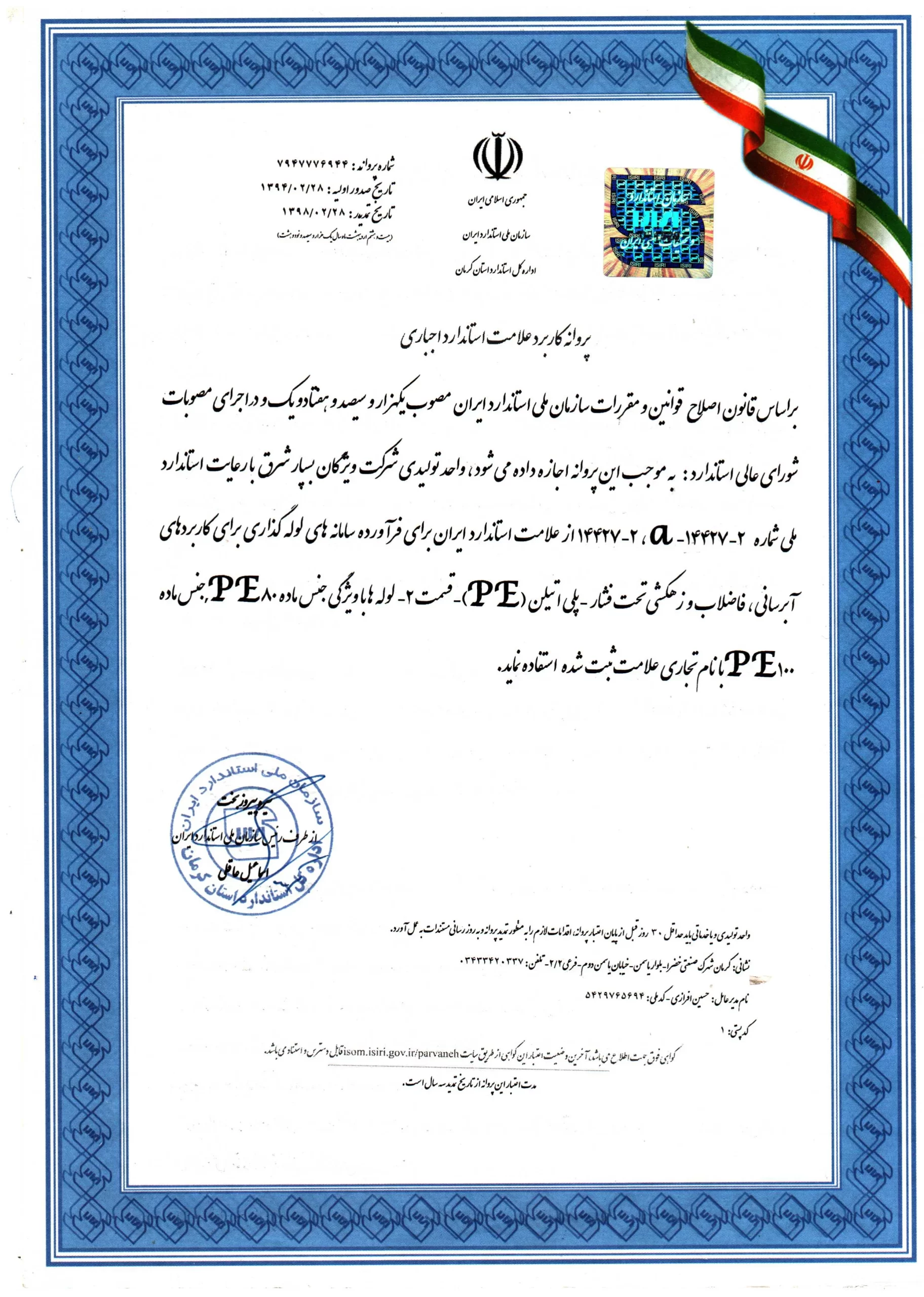

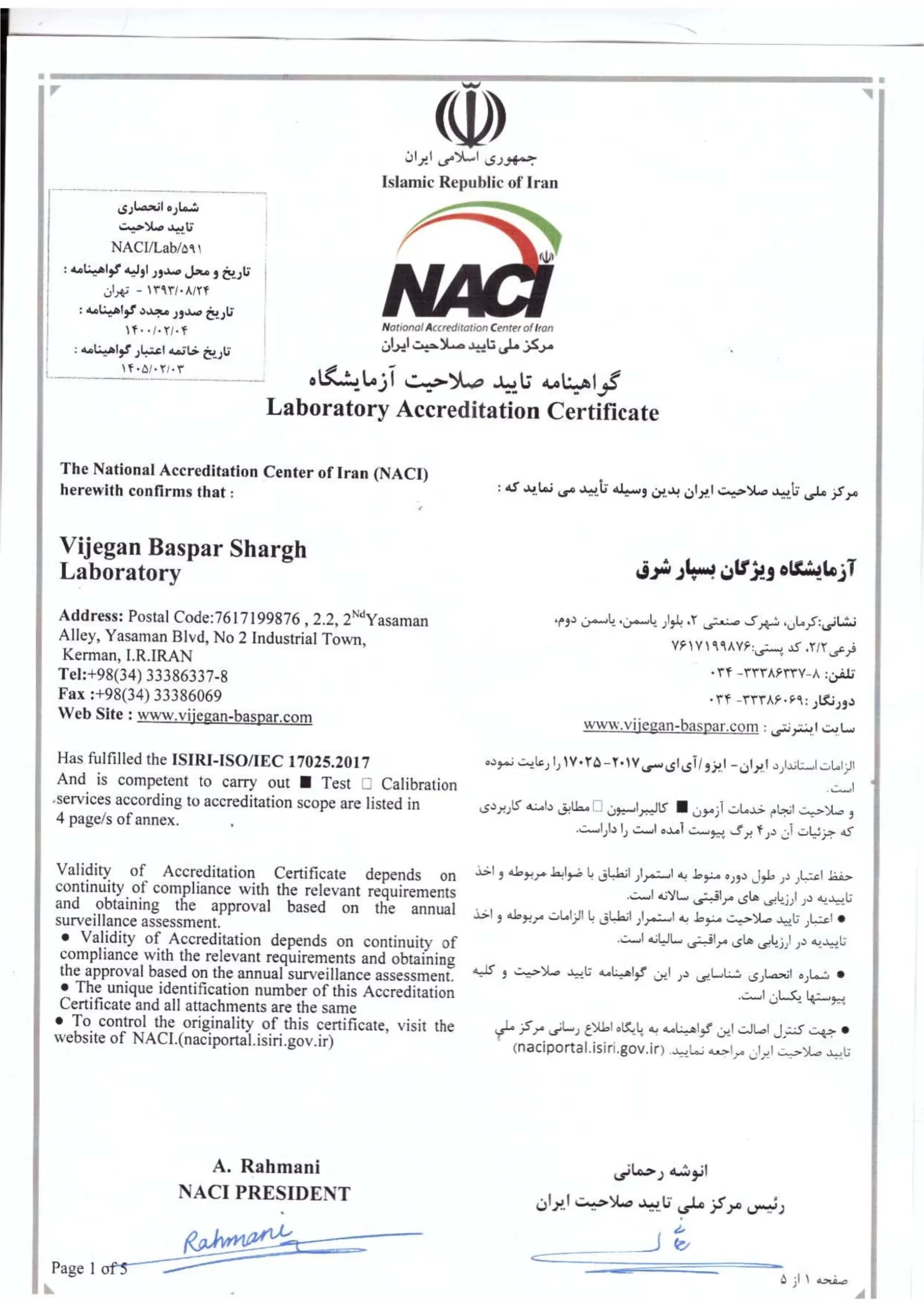

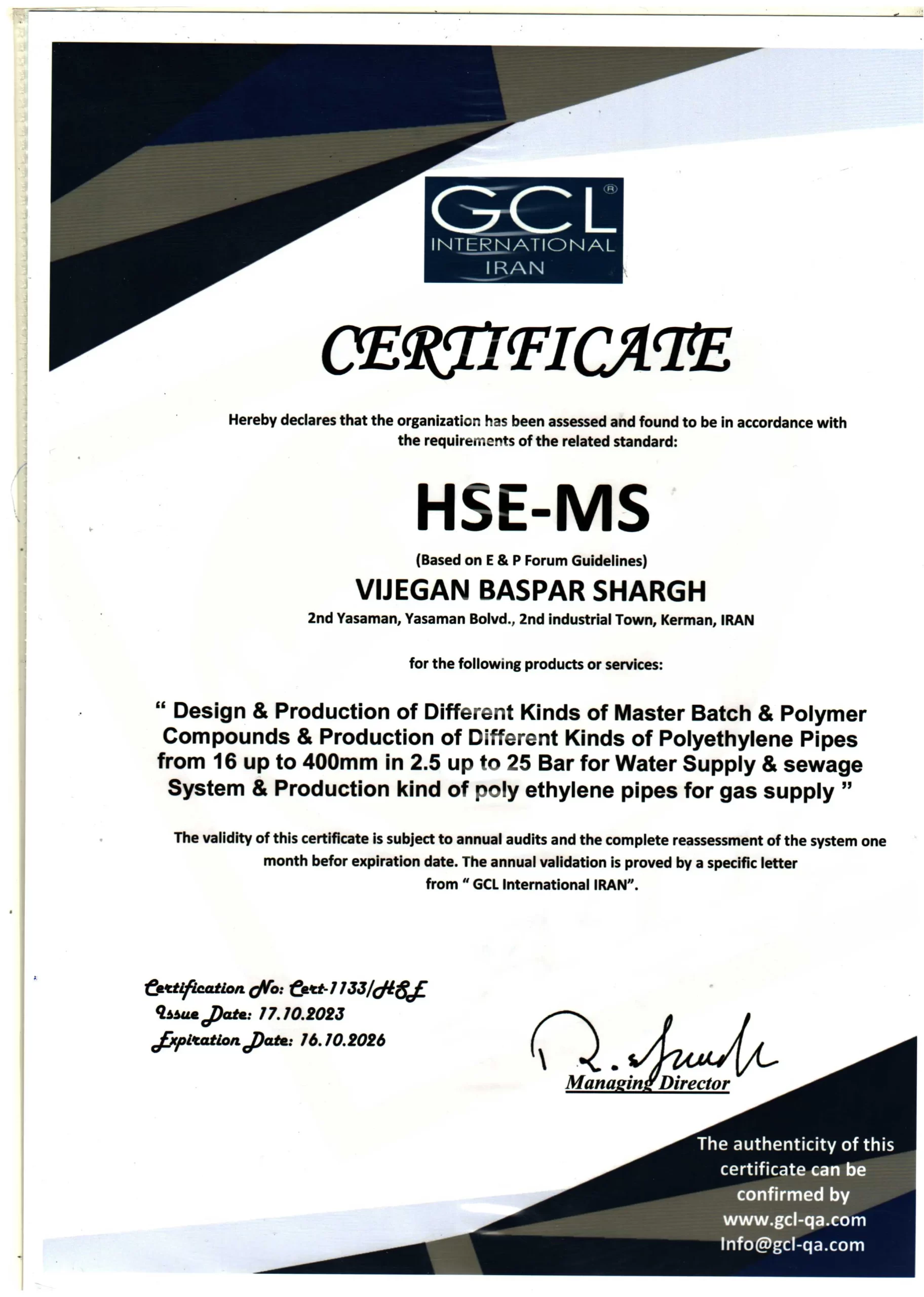

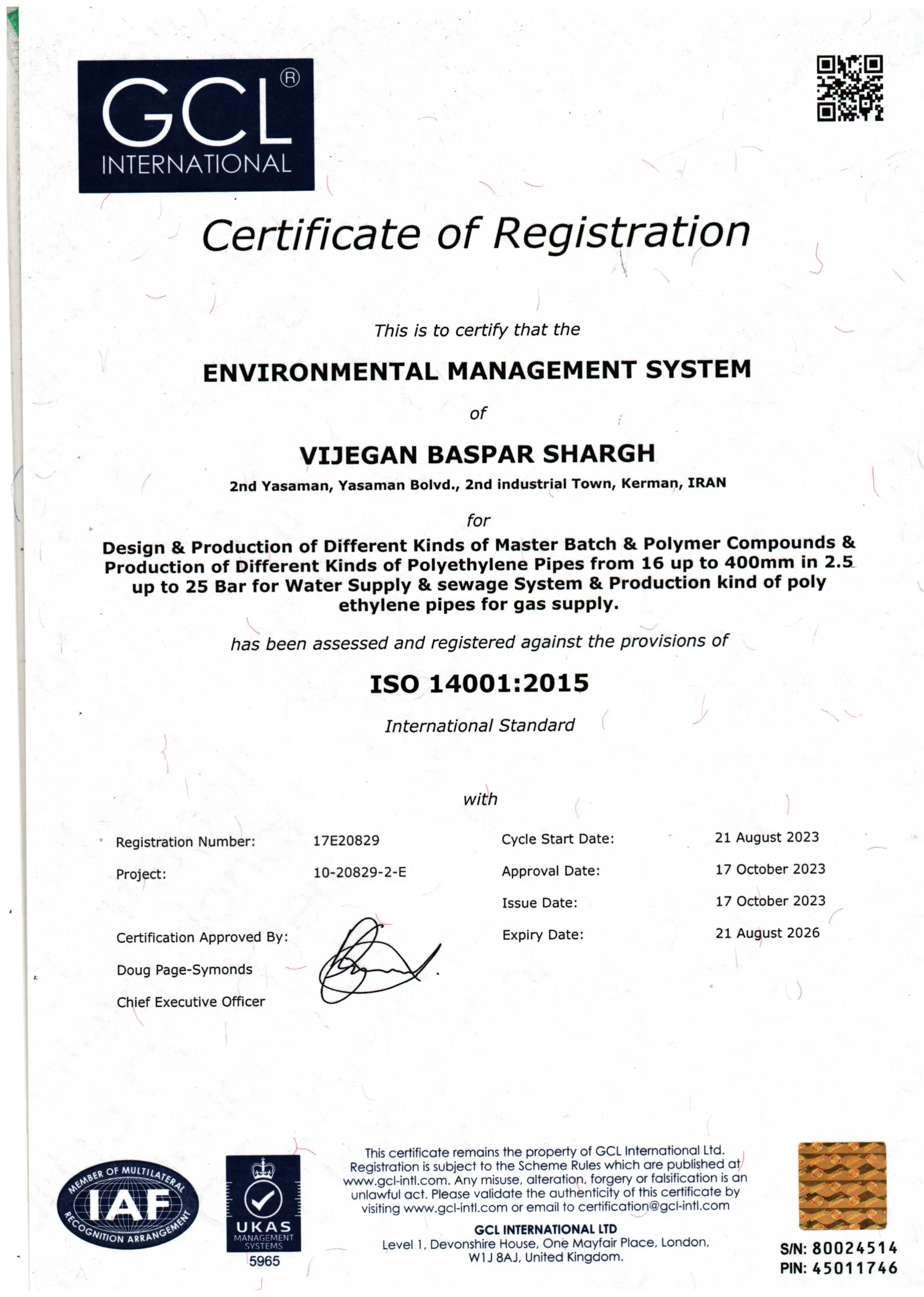

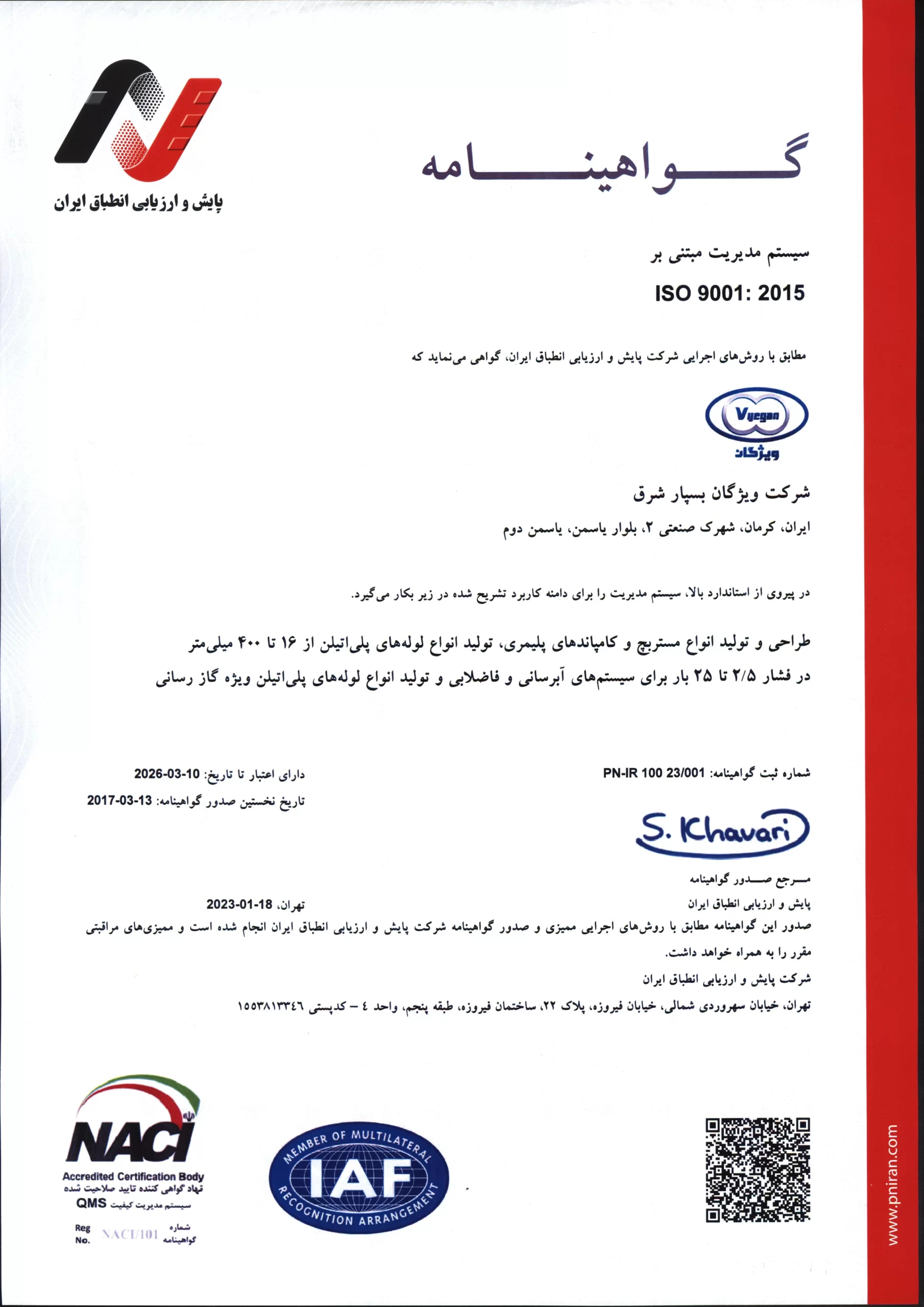

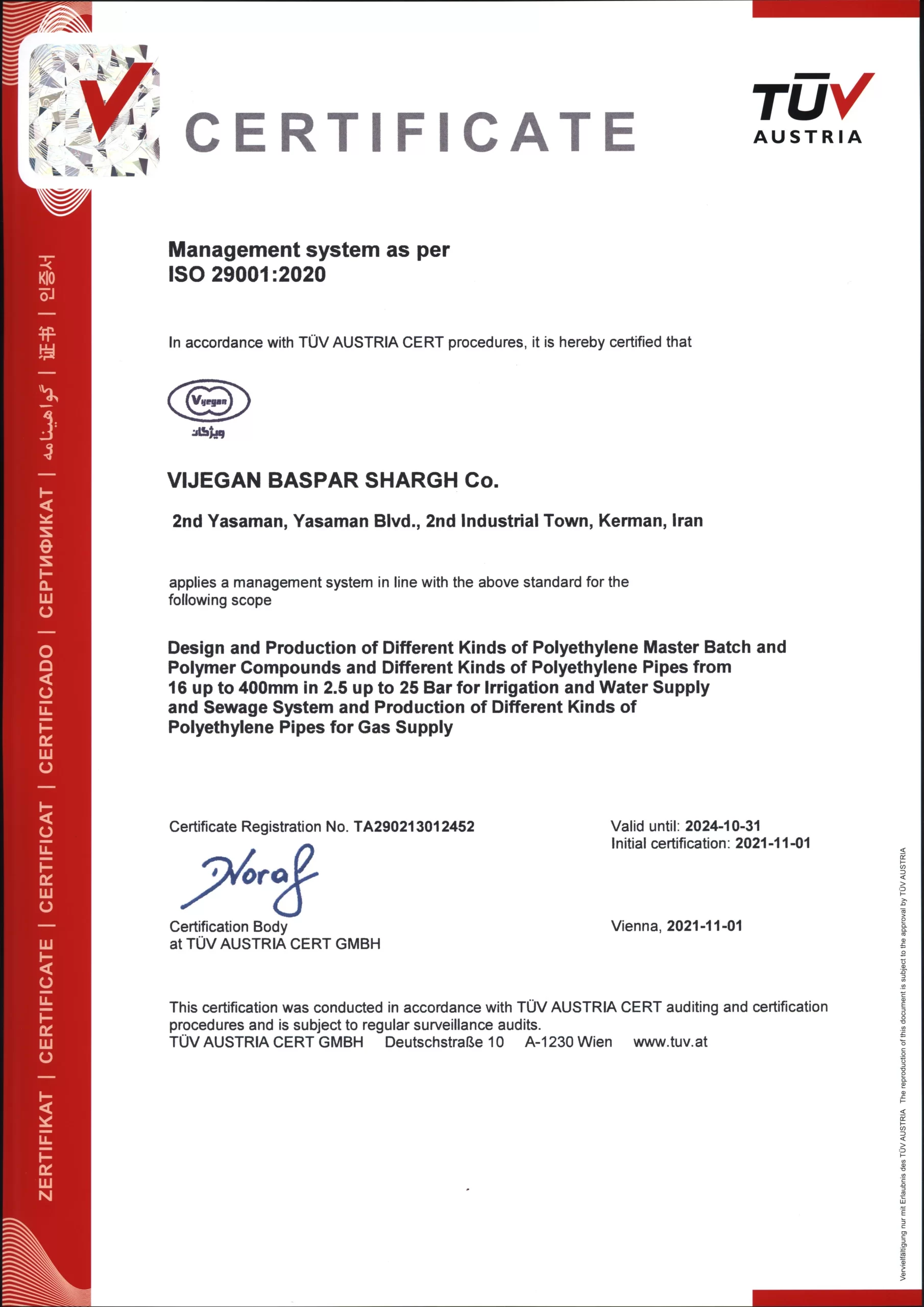

Vizhegan Baspar Sharq Company as one of the reliable companies in the field of design and production of masterbatch and polymer compounds and production of polyethylene pipes for water supply and lateral irrigation and production of polyethylene pipes for gas supply (used in oil, gas, petrochemical industries) and water supply) is active. This company has a laboratory with advanced equipment to perform various tests and has been approved by the National Qualification Center and is also a partner of Kerman Province Standards Department. This company is in order to achieve its important and strategic goals, including customer orientation and customer focus, development and production. Various products according to market needs, satisfying the stakeholders and its mission in the field of protecting the environment and the safety of its personnel, its integrated management system is based on ISO 9001, ISO14001, ISO 45001 and ISO 29001 standards.

Hossein Afrazi has a master’s degree in polymer from the University of Tehran and is the CEO of Vizhegan Bespar Sharq Company. This company started its business in 2010 under the brand Vizhegan Bespar, and in 2016, in the course of its development, it changed its name to Vizhegan Bespar Sharq. continued”

At that time, when I was in university, we were given a mission to monitor and investigate the production of polyethylene pipes in the country. After the surveys we conducted on the pipe manufacturing companies, we realized that the biggest weakness in the polyethylene pipe production industry is the poor quality of the masterbatches used in the pipes. At that time, the domestic masterbatches did not have much scientific basis and did not provide the necessary quality for the consumer, and most of the masterbatches for consumption were imported from abroad. Therefore, we decided to start our own masterbatches production unit with the desired quality. Importantly, we achieved this in 2010.

Associations and unions

Becoming a leading company in the production and supply of polymer products in the national and international markets

Vizhgan Bespar Sharq Company intends to rely on the technical knowledge of its personnel from all the actual and potential facilities in order to produce raw materials and downstream products of the petrochemical industries needed by the country in order to reduce dependence on imports and develop exports.

Vizhegan Bespar Sharq Company as one of the reliable companies in the field of design and production of masterbatch and polymer compounds and production of polyethylene pipes for water supply and lateral irrigation and production of polyethylene pipes for gas supply (used in oil and gas industries) , petrochemical and water supply) is active. This company has a laboratory with advanced equipment to perform various tests and has approval from the National Qualification Center and is also a partner of the provincial standards department. In order to achieve its important and strategic goals, including customer orientation and focus on the customer, development and production of diverse products according to market needs, satisfaction of stakeholders and the mission it has in the field of protecting the environment and the safety of its personnel, its integrated management system It is based on ISO 9001:2015, ISO/TS 29001:2020, ISO14001:2015, and ISO45001:2018 standards.

Based on this, the outlines of the organization’s integrated management system policy are:

Efforts to continuously improve the quality of manufactured products and product realization processes

Efforts to improve the level of satisfaction of the organization’s stakeholders, especially the company’s customers, through the timely and favorable performance of contracts and projects, as well as meeting their needs for special and special products.

Increasing the capabilities and competitive power of the company through identifying the support opportunities foreseen inside the country, obtaining advanced technologies, increasing technical knowledge, etc.

Increasing the amount of sales and gaining more market share inside and outside the country, improving productivity and developing the quality of human resources as the most efficient capital of the company.

and strive to provide a safe working environment for them, prevent water, air and soil pollution, optimize the consumption of resources and energy with the commitment to comply with the laws and requirements of safety, health and environment