Cables made with this product have high resistance to thermal oxidation. Also, the excellent dielectric properties of this product is one of the distinctive features of this product. Long life, resistance in high and low temperatures, resistance against corrosion and oxidation, good chemical stability, high flexibility and good thermal insulation are the most important features of this product.

| COMMERCIAL NAME : VB-3250W&C |

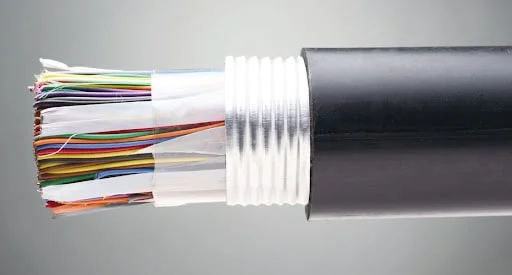

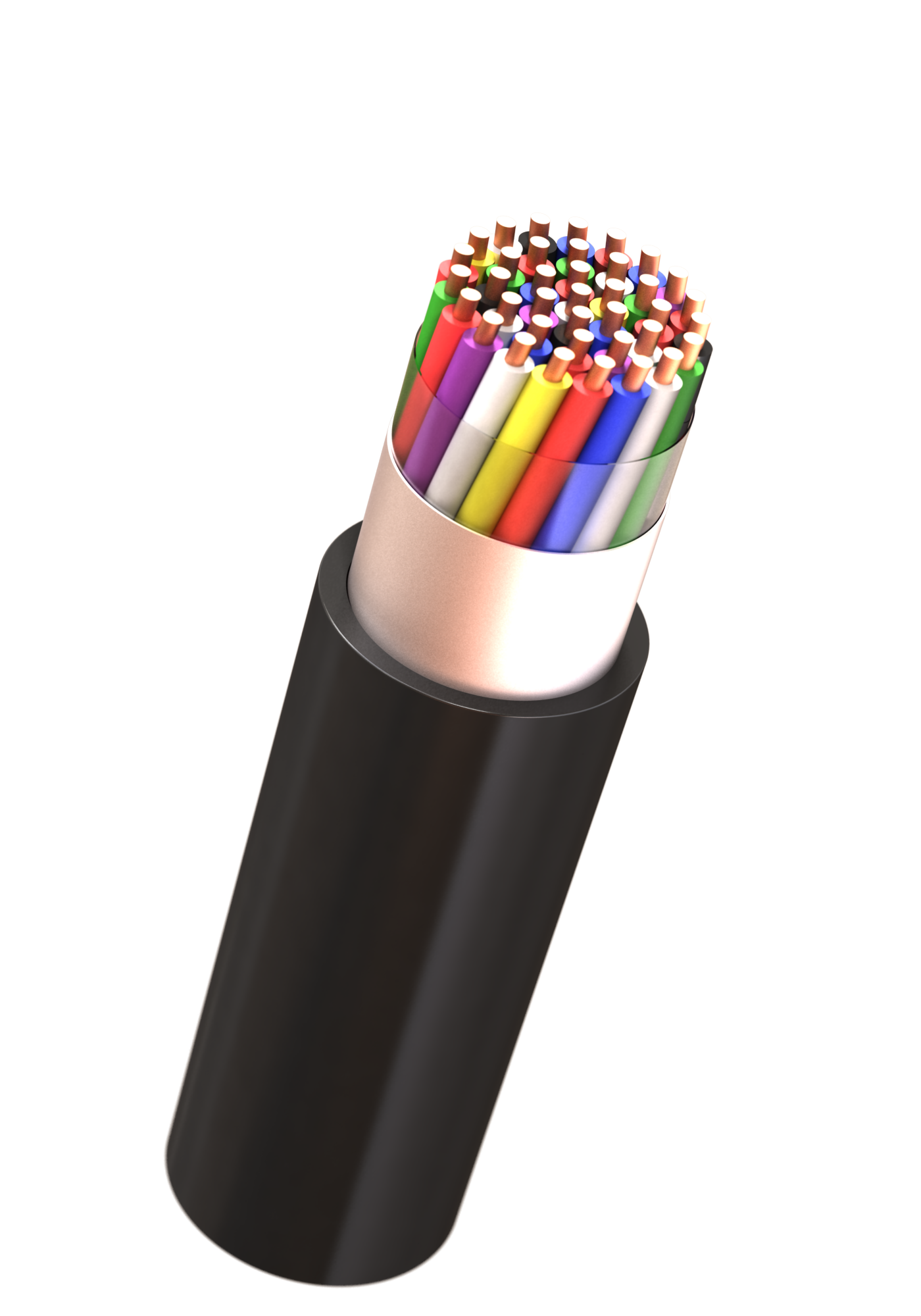

| Technical Name : Black LDPE Compound for Telecommunication Cables |

| Description: VB-3250 W&C is a black low density polyethylene grade with broad molecular weight and good melt strength, suitable for sheathing communication cables. This compound has stabilized against thermal and shears degradation and ensured long – term aging properties and demonstrates excellent extrude ability. VB-3250W&C has a long time service life due to excellent ESCR, weathering and UV resistance. |

| Color : black |

| Packaging:25 Kg bag |

| Application: Wire and cable coating, Telecommunication Cables |

| TECHNICAL DATA SHEET | |||

| Value | Unit | Test method | Property |

| <0.6 | gr/10 min | ISO 1133-1 | MFI (2.16kg, 190°C) |

| 0.933±0.003 | gr /cm³ | ISO 1183-1 | Density |

| >14 | Mpa | ISO 6259-1,3 | Tensile Strength at Yield |

| ≥500 | % | ISO 6259-1,3 | Elongation at Break |

| 2.25±0.25 | % | ISO 6964 | Carbon Black Content |

| ≥1000 | hours | ASTM D-1693 | Environmental Stress Crack Resistance(ESCR) |

| ≤3 | Grade | ISO 18553 | Carbon Black Dispersion |

| ≥25 | min | ISO 11357-6 | O.I.T(200°C) |

| 112±1 | °C | ISO 306 | Vicat Softening Point(1Kg) |